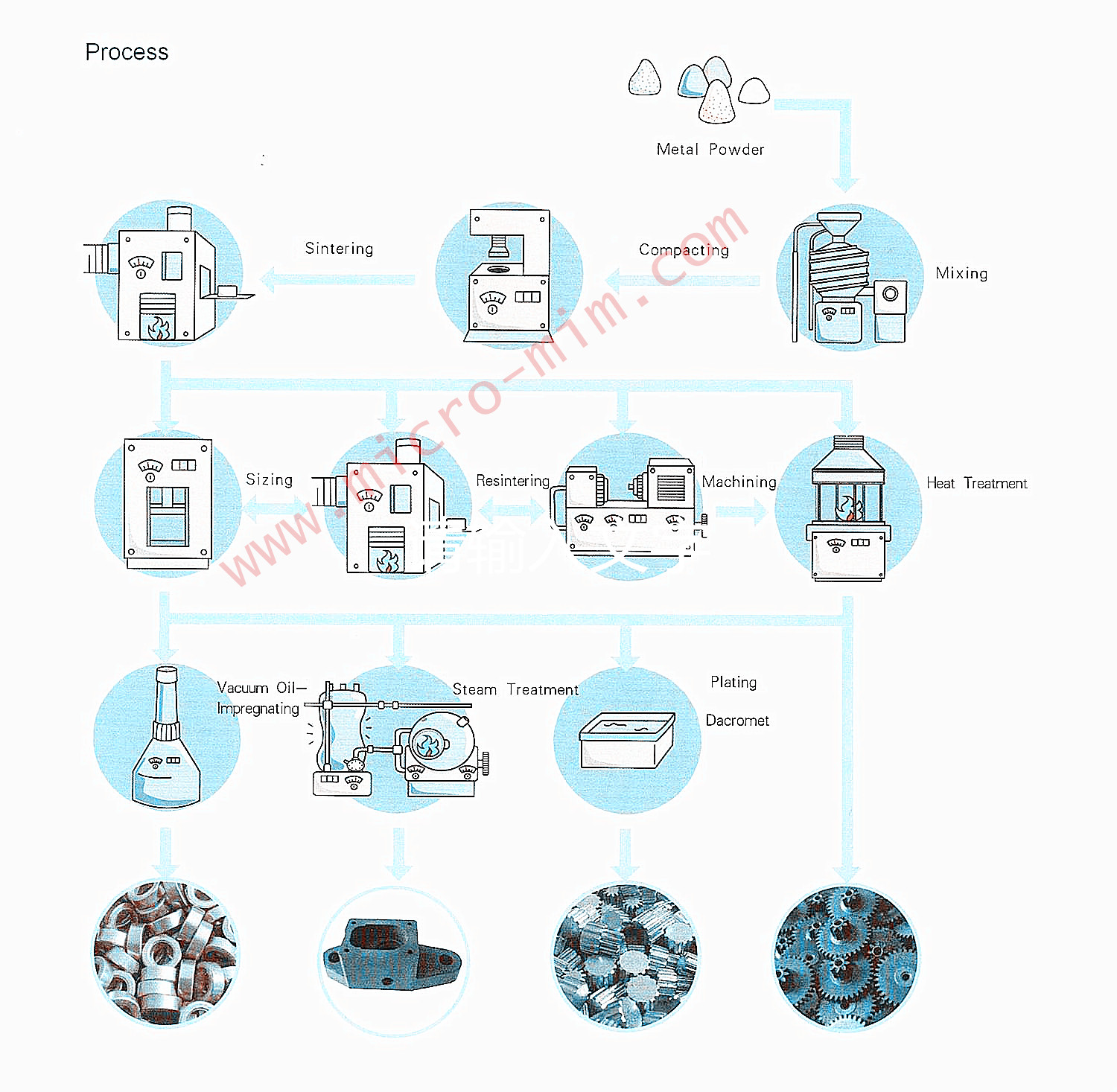

Powder Metallurgy

Process Concept of Powder Metallurgy

Powder Metallurgy is a kind of forming and sintering process with metal or nonmetal powder as raw material to make metal & composite material and components.

Powder Metallurgy Process Features

On material, Powder Metallurgy can produce special performance structural and function material, such as oil bearing with porosity control and soft magnetic and electric material with different ingredient combination.

On Machinery component manufacturing, Powder Metallurgy is a kind of no or less material cutting process to much decrease machining, save material and improve productivity. Also, with mould forming, Powder Metallurgy components are under very good control on dimension precision and consistency.

Material

Normal raw material is powder, such as Graphite, Iron, Copper, Stainless Steel and soft magnetic material. General material reference standards: GB(China), JIS(Janpan), Din(Germany), MPIF(US).

Iron-base Products

Material: Iron-carbon, Iron-copper-carbon, Low Alloy Steel, etc.

Type: Oil-impregnating Bearing, Bushing, Pulley, Gear, Cam, Connecting Road, etc.

Copper-based Products

Material: Copper-tin, Copper Coated Iron, etc.

Type: Oil-impregnating Bearing, Bushing, Gear, etc.

Stainless Steel Products

Material: SS304L, SS316L, etc.

Type: Drive Ring, Sleeve, etc.